Patina

Currently Australian Metals works with industry partners we supply to complete any patina work, based on specific projects we can put you in touch with professionals who specialise in a variety of outcomes to provide the results customers are requiring

Introduction

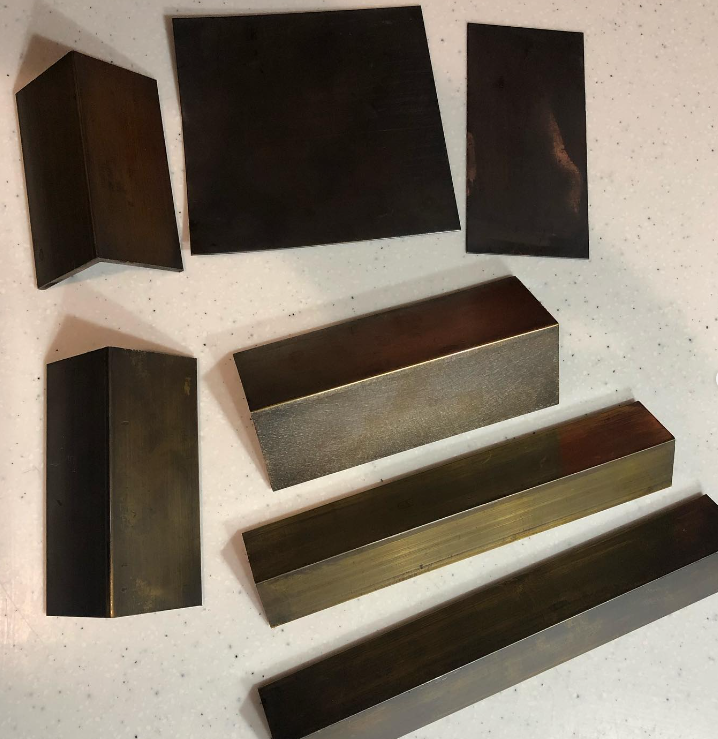

Copper brass and bronze, timeless and elegant metals, have been a staple in design and architecture for centuries. One of the most enchanting aspects is their ability to develop a patina, a layer that forms on the surface over time or through specific treatments, enhancing its aesthetic appeal. In this guide, we delve into the world of patina, exploring the various options, treatments, and methods to achieve stunning finishes.

Understanding Patina

Patina is a result of oxidation, where the metal reacts with elements in the environment, such as oxygen, moisture, and pollutants, forming a protective layer. This natural aging process can be accelerated or manipulated through various treatments, offering a spectrum of colors from deep browns to vibrant greens. Understanding the science behind patina is key to mastering its application and maintaining the desired finish.

Options for Patina

- Natural Patina: Over time, develops a natural patina, showcasing a range of warm, earthy tones. This gradual change adds character and a sense of history to the metal.

- Forced Patina: For those who prefer a more immediate transformation, forced patina involves applying chemicals to the surface. Common agents include vinegar, ammonia, and salt, which can be used to create varying shades and patterns.

- Patina Through Heat: Applying heat can also induce patina, resulting in a unique and often unpredictable pattern of colors.

Treatments for Patina

- Chemical Treatment: This is the most controlled method for creating patina. Solutions containing nitrates, sulfates, and chlorides are applied to the surface, and the reaction time is carefully monitored to achieve the desired effect.

- Natural Aging: Exposing to the elements allows it to develop a patina naturally. This method requires patience but results in a truly authentic aged appearance.

- Protective Coatings: After achieving the desired patina, applying a clear lacquer or wax can preserve the finish and protect the surface from further changes.

Methods to Complete Patina

- Preparation: Clean thoroughly to remove any oils or dirt. This ensures an even application of patina agents.

- Application: Apply the chosen patina agent using a brush, sponge, or spray. Techniques like dabbing, sponging, or spraying can create different effects.

- Neutralization and Sealing: Once the desired patina is achieved, neutralize the chemical reaction (if necessary) and seal the finish with a protective coating to maintain its appearance.

The art of creating a patina is a blend of science and creativity. Whether you prefer the slow charm of natural aging or the swift transformation through chemical treatments, the options are vast. By understanding and applying the various treatments and methods, you can achieve a range of exquisite finishes that add depth and character to your pieces. Embrace the beauty of patina and let your creative visions come to life.